High precision aspherical glass lens by molding

The most notable benefit of aspheric lenses is their ability to correct for spherical aberration, an optical effect which causes incident light rays to focus at different points when forming an image, creating a blur. Spherical aberration is commonly seen in spherical lenses, such as plano-convex or double-convex lens shapes, but aspheric lenses focus light to a small point, creating comparatively no blur and improving image quality. Spherical aberration is inherent in the basic shape of a spherical surface and is independent of alignment or manufacturing errors; in other words, a perfectly designed and manufactured spherical lens will still inherently exhibit spherical aberration. An aspheric lens can be designed to minimize aberration by adjusting the conic constant and aspheric coefficients of the curved surface of the lens. Figure 1 shows a spherical lens with significant spherical aberration compared to an aspheric lens with practically no spherical aberration.

Precision glass molding is a manufacturing technique where optical glass cores are heated to high temperatures until the surface becomes malleable enough to be pressed into an aspheric mold (see Figure 4). After the cores cool down to room temperature, the resulting lenses maintain the shape of the mold. Creating the mold has high initial startup costs because the mold must be precisely made from very durable material that can maintain a smooth surface, while the mold geometry needs to take into account any shrinkage of the glass in order to yield the desired aspheric shape. However, once the mold is finished the incremental cost for each lens is lower than that of standard manufacturing techniques for aspheres, making this technique a great option for high volume production.

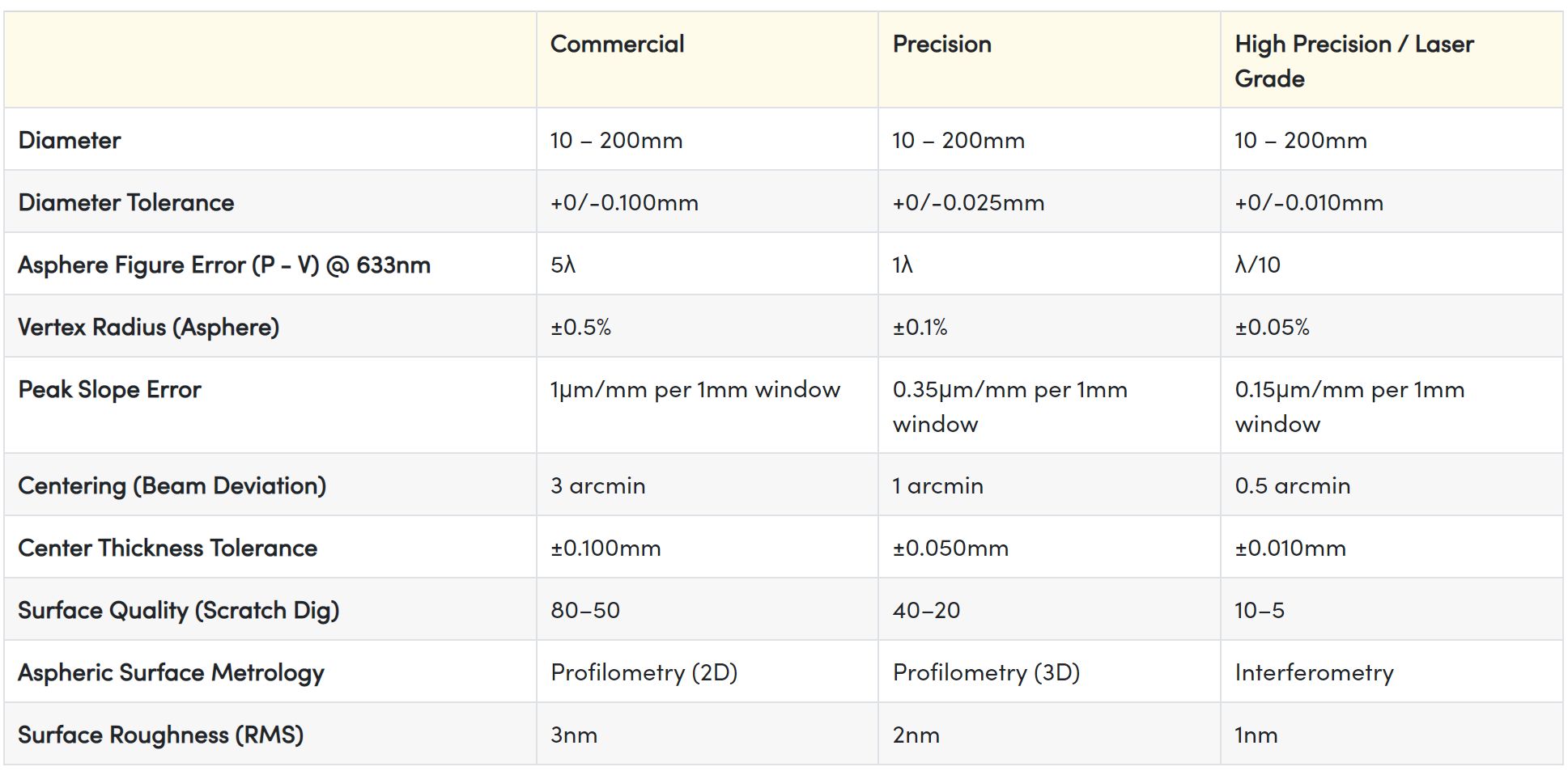

Specifications

Test Equipment:

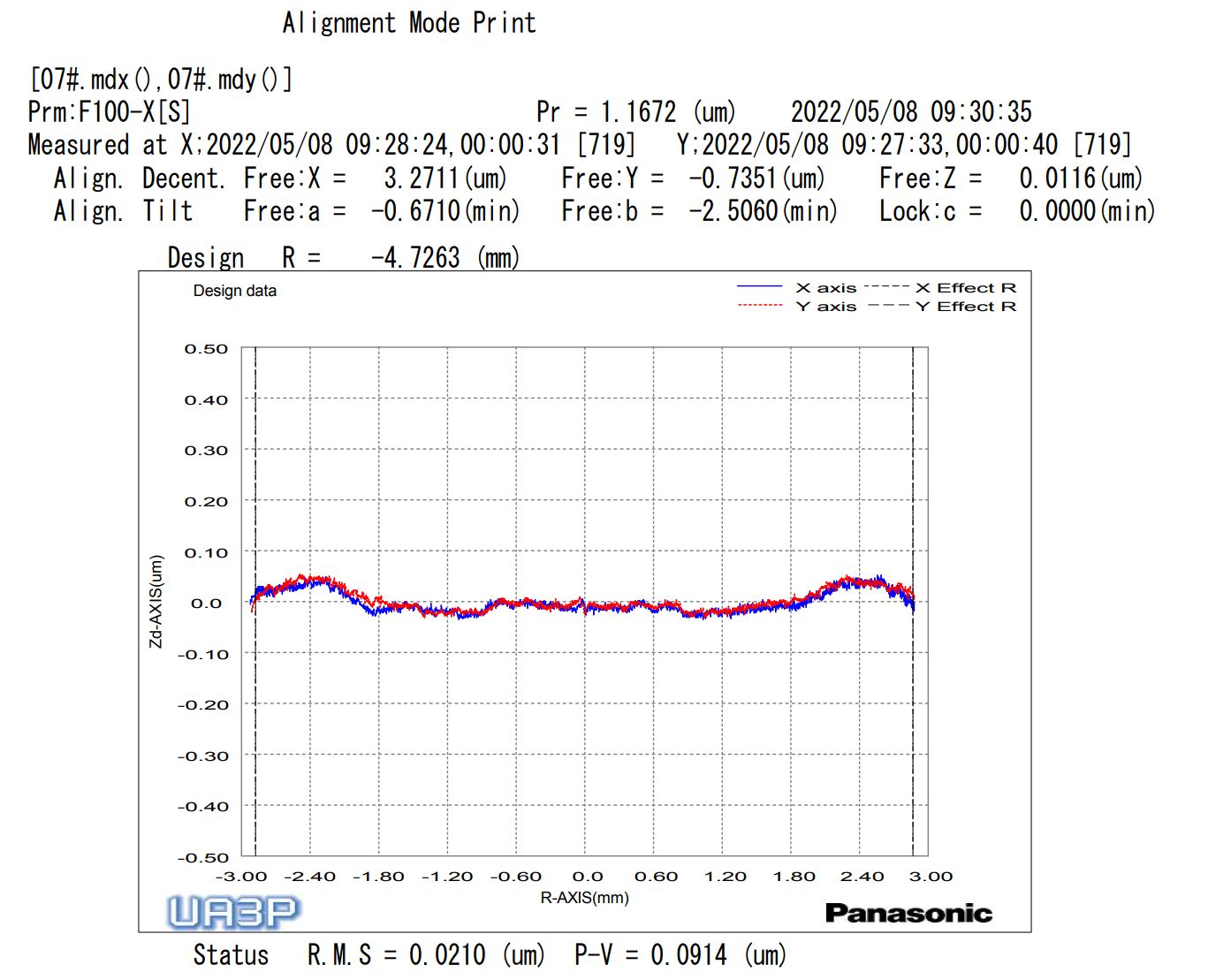

Test Report :