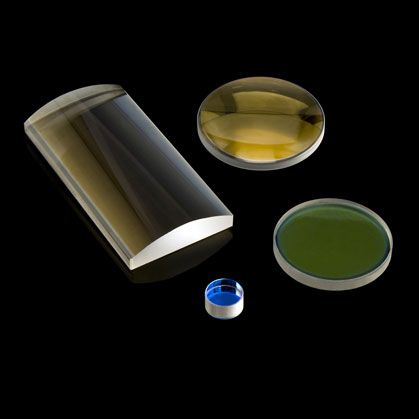

fused silica /Sapphire glass lens for high precision laser optics

Optical Windows

DG optics has established a consistent production and quality control system from optics design, through growth of the optical crystal, to polishing and coating to respond to customer demands as quick as an all-round manufacturer of laser optics. Please contact us with specific requests if you require other specifications for lenses and mirrors.

Laser optics includes all the optical elements and optical systems used within lasers, or for manipulating—or transmitting—laser light. Laser optics components have more stringent requirements on surface quality and coating when comparing with standard imaging optics. Surface quality must be high in sensitive laser applications, especially for laser mirrors and prisms. Optical losses must be minimized. Components must have high laser damage thresholds, especially if they are to be used with high-energy pulsed lasers such as Q-switched high power lasers.

DG Optics manufactures a wide range of high precision laser optics. Our state of the art equipment allows us to manufacture high quality optics components that perform consistently under even the most demanding conditions, and are suitable for use in CO2 lasers, high power fiber lasers, solid state lasers, and laser diodes. Our line of laser optics includes laser lenses, laser line filters, prism mirrors, and laser line beamsplitters.

Laser optics can be made of a variety of substrates, including BK7, H-K9L, Sapphire, UV grade fused silica, IR grade fused silica, calcium fluoride (CaF2), magnesium fluoride (MgF2), zinc selenide (ZnSe), Zinc Sulfide (ZnS), Gallium Arsenide (GaAs), germanium (Ge) and silicon (Si). Dielectric coatings are often used to improve mirror reflectivity for both S and P polarizations. For most laser applications, filter transmission or reflectance over a very narrow band (the laser line width) is key, and both the substrates and coatings must be chosen carefully for improving optical performance of the laser-based devices. Ultrashort pulse lasers are the exception to this rule; they have a large spectral bandwidth and require lenses and filters with broad transmission ranges.

Custom Laser Optics

Although we offer a wide range of off-the-shelf optics products, we are also able to design and manufacture custom optical components including laser lenses, filters, and beamsplitters according to your exact specifications. Our in-house design and manufacturing capabilities make us quickly deliver optical solutions that best fit your application. With over fifty five years of experience as a designer and manufacturer of high quality optical products, we ensure the designs meet your requirements and your project run smoothly from design to prototype to volume production as intended.